Fire Supression Systems

Home > Fire Supression Systems > Oxygen Reduction Fire Prevention System

Oxygen Reduction System

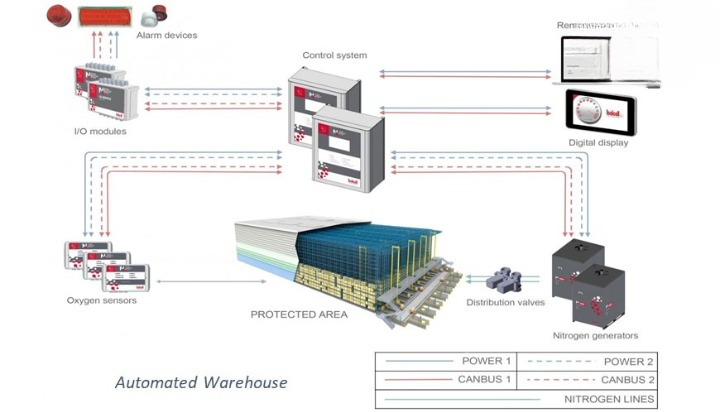

N2 OXYGEN REDUCTION SYSTEM, Prevent fires before they start. All traditional firefighting technologies have the same problem in common. They are being used once the damage has occurred already.

Whatever media is in use, foam, water mist, sprinklers, gas or water they are being activated after a fire has been detected. With the common and known methods fire is being fought only reactively.

Often the damage caused by the extinguishing media is worse than the damage caused by the fire itself. Furthermore, there are many applications where the usage of water or gas would be fatal in its consequence. Applications like e.g. Data Centers, Server Rooms, Cold Stores, Paper Mills and many more. Whenever electricity comes into play the usage of water could end in a total disaster. Huge storages like cold store could not be flooded from a gas reservoir for example.

Aims to provide the optimal solution for most of the above-mentioned applications to ensure absolute security by simply making the development of a fire impossible, replacing traditional firefighting technologies.

“Completely eliminating the fire hazard and safeguarding people, buildings and its content is possible with ISOLCELL’s N2 ORS oxygen depletion systems”.

Advantages

- Eliminates the risk of fire

- Zero false alarms

- Constant protection (24/7)

- Business continuity

- No false activation

- No manual activation necessary

- No damage caused by extinguishing agents

- No residue

- Adaptable oxygen concentration (according to the material to be protected)

- Natural

- User-friendly

- Tolerable for people

Additional Advantages

- Accuracy of the virtual grid

- Greater adaptability in relation to the area to be protected

- Regulated and certified system

- Redundancy of the system

- Greater safety in oxygen measurement

- Fitted with self-diagnostic tools

- Plug & play installation

- Easily reprogrammable

- System visible by remote

- Also adaptable in areas subject to regulatory constraints

- Can be produced for any risk class

- Can be integrated into pre-existing systems

- Extensive customisation options

- Minimally invasive in the area to be protected

- Silent

- Lower management and maintenance costs

- Limited energy consumption

Application Areas

- Paper Mills

- Refrigerated Warehouses

- Food Warehouses

- Storage of Hazardous Materials

- Automated / Intensives Warehouses

- HBW (High-Bay Warehouses)

- ASRS Warehouses (Automated Storage Retrieval System)

- Fire Protection for Automated High-Bay Warehouses

- Cool Stores, Freezer Warehouses

Data Sheet

Brochure

get in touch