Fire Detection & Suppression System (FDSS) and Fire Detection & Alarm System (FDAS)

About

Fire Detection & Suppression System In Bus/cars

Public Transport Buses play an important role in providing public transport for dedicated services between suburbs and connecting the last mile of every city and adjoining areas. In recent years, we have seen significant changes in relation to safety in the Bus Transport sector. Fire represents one of the main incident types. Bus Fires are a relatively common and potentially devastating occurrence in the world today, with many fires occurring every day across the globe. Without protection, a bus can be completely destroyed by the uncontrolled growth of a small fire in a very short space of time.

Fire in the engine compartment may occur for several reasons. Engine parts such as the manifold and turbocharger may reach temperatures high enough to cause leaking fuel or oil to ignite. Fires may also occur because of short circuits in electrical wiring and the overheating of engine components or the braking system. The conditions in the engine compartment on buses are challenging for managing the risk of fire.

The Solution

Looking at the condition, there were few amendments in the Automotive Industry Standard. Under AIS-135 it has been made mandatory to have detection and an alarm system with possible suppression for any such fire. The System is known as Fire detection and suppression system (FDSS), it is an integration of two systems one is Fire detection and another one is Fire suppression / extinguishing system. The other system is, Fire Detection and Alarm System (FDAS) which has an automatic trigger Alarm system in case of fire.

The UL, VdS, FM approved Detection system (which detects the fire and automatically activates the Suppression / Extinguishing system)

Line Type Heat Detection System works on the principle of change in the volume of gases (air) with temperature changes in a closed / sealed sensor tube.

The Pneumatically tight system is formed by the sensor tube, which is sealed at its one end and connected to the detector box at its other end. This pneumatic line volumetric capacity contains normal air at ambient pressure and this is connected to the line type heat detector which senses the change in pressure with the increase in temperature outside in the environment of a confined space.

If the pressure in the sensor tube increases due to rise in the temperature of the protected area beyond the threshold values, the system triggers an alarm, which in turn is used to actuate an Extinguishing System.

When used for fire detection, the non-pressurized sealed S.S. metal sensor tube is laid inside the engine compartment. On detection of fire, the system shall operate the extinguishing system.

The DCP Based extinguishing system

The Extinguishing system is designed to be a primary device, which deploys UL Listed DCP (ABC 90%) onto the fire within the first few seconds of it being detected. The aim is to contain and suppress / extinguish a fire before it develops into a fully evolved fire.

Based on the type of engine compartment the number of Cylinders varies accordingly. Each DCP discharging units complete with their deployment facilities consists of a solenoid valve, pressure gauge and safety valve, SS Nozzles and Rigid Pipes, etc. Each unit (Cylinder) is coupled to DCP distribution manifold piping.

The distribution manifolds are fitted with an array of specially designed DCP discharge nozzles, which delivers low expansion DCP directly inside the engine compartment area.

The System quickly detects any unusual rate of rise in temperature & Max Temperature, which can lead to a possible fire. It not only raise an Alarm, but it also initiates suppression part (can be triggered automatically / manually by detection unit) to suppress any incipient fire.

Features & Benefits

Detection

- Quick detection – 3-10 Seconds

- Reusable / Resettable Sensor

- Built-in self-check module

- It records the event, which are stored in non-volatile memory of the detector (up to 16MN event can be stored)

Alarm System

- Auto Triggered by Detection System

- Audio-Visual alarm for alerting passengers & Driver

Suppression

- SS Nozzles & Hoses

- Mono Ammonium Phosphate MAP (90%).

- Multiple Control Method: Manual, Remote & Wireless

- Flow: Fixed and variable flow(optional)

- UL-Listed

Certifications

- System Type Approval – AIS 135

- EMI EMC as per AIS 004 (Part 3)

- Detection - UL / VdS / FM

- Suppression – ISI approved

Unique Points

- Quickest Detection possible

- Robust & Reusable System

- Customizable for all the large vehicles.

- Minimal to No Maintenance

- Highly Efficient & Reliable System

Applications

- All the Passenger / School Buses

- Private / Public, Commercial Material Vehicles

- Gas Container Truck

- Card etc.

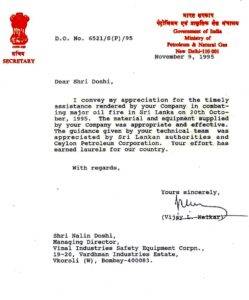

Approvals

Video

FAQ

Item #1

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Item #2

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Item #3

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

get in touch

10500 USGPM FOAM MONITOR

10500 USGPM FOAM MONITOR