Centralised Fixed Foam Feeding System (CFFFS)

Centralised Fixed Foam Feeding System (CFFFS)

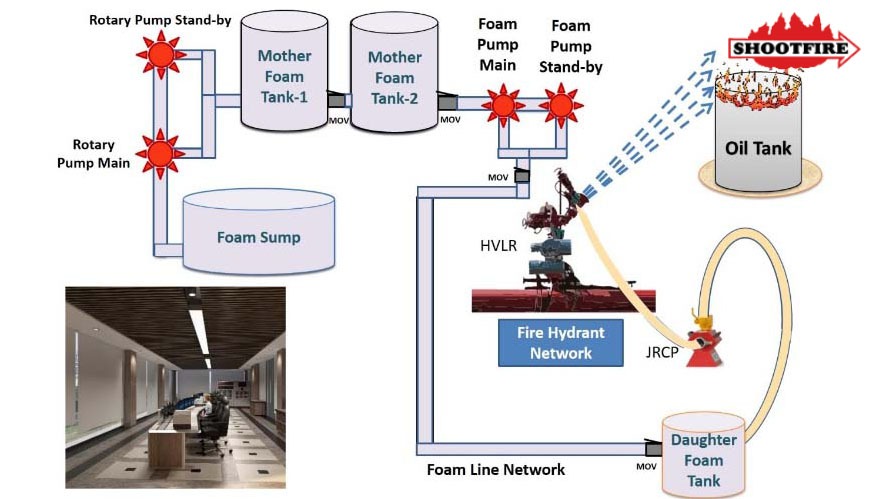

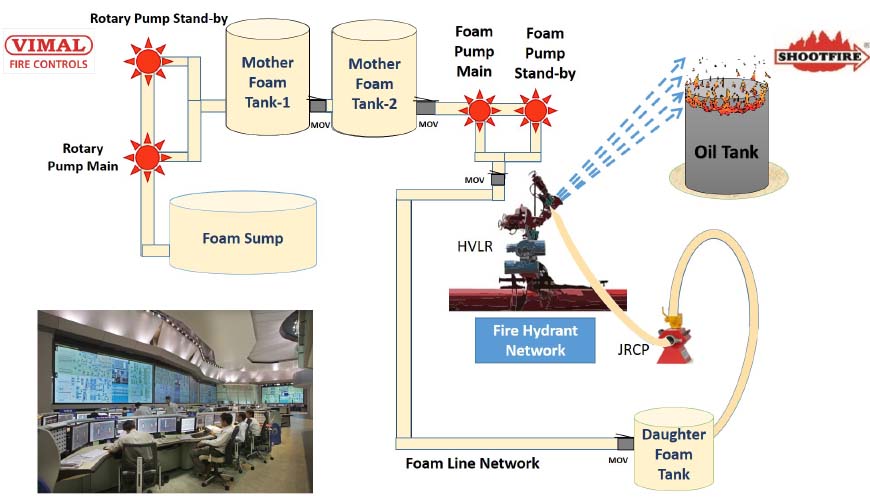

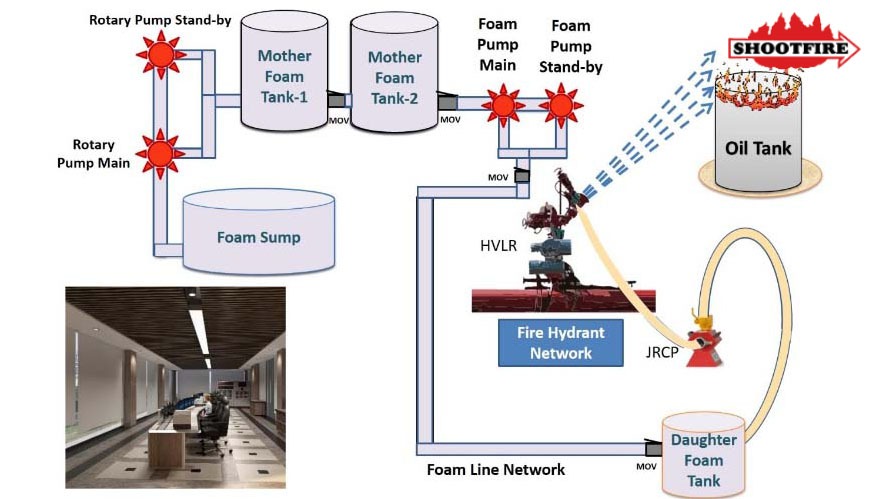

Centralised Fixed Foam Feeding System (CFFFS) is our latest innovation in the field of Fire Fighting Technology. It’s a product developed based on our experience of fighting full surface areas. One of the main hindrances in launching a Fire attack is the continuous supply of water and foam for 65 Minutes as per NFPA 11 or OISD standards.

CFFFS is a SMART system designed to feed water and foam to remote / portable / manual HVLR monitors, MEFFG, etc continuously without any stoppage thereby making the fire fighting operation effective and simultaneously alerting the personnel at the facilities so that they can respond to the incident.

In CFFFS, the foam feeding is piped from a centralised foam station (comprising of tanks, pumps etc.) and discharged through fixed or portable delivery outlets (daughter tanks) to multiple Manual and remote HVLR monitors, MEFFG, Portable Monitors etc. The Foam piping is a ring network and is divided into four areas across the installation / terminal / depot viz. MS tank farm area, HSD tank farm area, Pump House area and TLF area. It has a provision that each area can be isolated from other area for maintenance, flushing and draining purpose.

The entire system is highly automated, and it requires minimal human intervention. CFFFS continuously keeps a check on the health of the whole system including:-

- HVLR Monitor controls

- Water Pump

- Water level in tanks for overfill protection

- Hydrant pipeline pressure

- Foam level in both main Foam tank and the Daughter tank.

The system is designed for maximum safety and high availability time. As a minimum, the following fail-safe features are incorporated:-

- Failure of mains power to control panel: In the event of power failure to the control panel, UPS provided automatically and seamlessly ( smooth transfer) takes over to ensure power supply for 90 minutes of continuous operation.

- Failure of Foam Pumps: The system has features to detect and initiate alarm in case of failure of pumps. In case of Failure of main foam pump, the standby foam pump is initiated.

- Leak in the foam lines: The system can detect leak in the foam lines which ensures wastage of foam is avoided due to such leaks in the foam lines and the system is efficient during a Fire Attack.

Features

- SMART HVLR Software – Data Analysis, Alarms, Alerts, execution of Upgraded HVLR Operation.

- SMART upgraded HVLR MONITOR - Simultaneously Transmits feedback of its Position.

- Continuity of Foam supply is ensured using Smart management.

- Option of sending SOS call to various electronic media like Email, SMS etc.

- Flexible installation options include numerous base options and a hydrant mounting choice

- Light weight device

- Foam induction ratio is 1:3 to 1:4 @ 1% & 3% induction

- Self-induction with a pick-up tube of length 4mtrs.(max)

- Pressure gauge for online inlet pressure monitoring

Benefits

- The system will make Fire Fighting smarter & responsive in line with SMART TERMINAL concept. Compliant with OISD 117 & OISD 244.

- 24X7 monitoring of Assets and immediate launch of fire attack is possible in case of fire detection.

- Reduced human intervention for firefighting.

- Suppression of fire at incipient stages saving highly valuable assets.

- Real-time monitoring and display of information.

- Inbuilt Fault Diagnostic Features make the System Reliable & Responsive.

Approvals

Video

get in touch

Centralised Fixed Foam Feeding System (CFFFS)

Centralised Fixed Foam Feeding System (CFFFS)