Introduction

The oil and gas industry is a vital part of the global economy, providing energy that powers industries, homes, and transportation. However, it also presents significant fire safety challenges due to the highly flammable nature of the materials involved, complex infrastructure, and remote locations. Ensuring fire safety in this sector requires specialized equipment and innovative solutions. This blog explores the unique fire safety challenges faced by the oil and gas industry and highlights how specialized equipment and practices can address these issues.

Understanding the Fire Safety Challenges in the Oil and Gas Industry

Flammable Materials and High Risk of Explosions

Explanation: The oil and gas sector deals with hydrocarbons, which are highly flammable and can cause catastrophic fires and explosions if not handled correctly. From drilling rigs and refineries to storage facilities and pipelines, the risk of ignition is omnipresent. Even a small spark can lead to a massive fire, endangering lives, causing environmental damage, and leading to significant financial losses.

Details:

- Hydrocarbon Properties: Hydrocarbons like crude oil, natural gas, and refined petroleum products are volatile and can easily vaporize, forming flammable mixtures with air. This increases the risk of fires and explosions.

- Ignition Sources: Common sources of ignition include static electricity, equipment malfunctions, human error, and lightning strikes. Managing these risks requires stringent safety protocols and regular maintenance.

Complex Infrastructure

Explanation: Oil and gas facilities often have complex infrastructures, including pipelines, storage tanks, and processing units, which are interconnected and spread over vast areas. This complexity makes it challenging to implement and maintain comprehensive fire safety measures. Ensuring that all components of the infrastructure are protected and that fire suppression systems are integrated and functional requires meticulous planning and execution.

Details:

- Interconnected Systems: The interconnectivity of pipelines, processing units, and storage tanks means that a fire in one area can quickly spread to others, making it crucial to have integrated fire safety systems.

- Accessibility Challenges: Components of the infrastructure may be located in hard-to-reach areas, complicating the installation and maintenance of fire suppression systems.

Remote Locations

Explanation: Many oil and gas operations are located in remote and inaccessible areas, such as offshore drilling platforms, desert regions, and arctic zones. These locations pose logistical challenges for fire safety, including the transportation and installation of fire fighting equipment and the availability of trained personnel. In the event of a fire, response times can be significantly delayed, exacerbating the potential damage.

Details:

- Offshore Platforms: These are isolated and surrounded by water, making traditional fire fighting approaches less feasible. Specialized equipment and vessels are required for effective fire suppression.

- Desert and Arctic Conditions: Extreme temperatures and environmental conditions in these regions require equipment that can withstand harsh climates and remain operational.

Harsh Environmental Conditions

Explanation: The environmental conditions in which oil and gas facilities operate can be harsh and unpredictable. Extreme temperatures, high winds, saltwater corrosion, and seismic activity are just a few factors that can impact fire safety systems. Equipment must be robust and resilient to withstand these conditions while maintaining effectiveness.

Details:

- Temperature Extremes: Both high and low temperatures can affect the performance of fire safety equipment. For example, extremely low temperatures can cause water in pipes to freeze, while high temperatures can affect the integrity of materials.

- Corrosion: Saltwater corrosion, particularly in offshore environments, can degrade fire safety equipment, requiring the use of corrosion-resistant materials.

Solutions for Fire Safety in the Oil and Gas Industry

Specialized Fire Suppression Systems

Explanation: Specialized fire suppression systems are essential in the oil and gas industry. These systems are designed to detect and extinguish fires quickly, minimizing damage and preventing escalation. Gas-based suppression systems, such as those using CO2, Novec 1230, and HFC 227ea, are effective for enclosed areas like control rooms and engine compartments. Inergen and Argonite systems are inert gas solutions that reduce oxygen levels to extinguish fires without damaging sensitive equipment.

Details:

- CO2 Systems: Effective in extinguishing fires in confined spaces by displacing oxygen. Ideal for areas where water damage is a concern.

- Novec 1230 and HFC 227ea: Clean agent fire suppressants that do not leave residue, making them suitable for protecting sensitive electronic equipment.

- Inergen and Argonite: Inert gas systems that lower oxygen levels to non-combustible levels, effective in occupied areas due to their safety for humans.

Advanced Detection Technologies

Explanation: Early detection of fires is critical in preventing large-scale disasters. Advanced detection technologies, such as video-based fire detection systems and sensor-based linear heat detection systems, provide real-time monitoring and early warning. These systems can detect anomalies, such as temperature spikes or smoke, and trigger alarms and suppression systems before a fire spreads.

Details:

- Video-Based Detection: Uses algorithms to analyze video footage for signs of smoke or fire, providing visual confirmation and reducing false alarms.

- Sensor-Based Detection: Linear heat detection systems use heat-sensitive cables that detect temperature changes along their length, providing accurate localization of fire hazards.

Robust Fire Fighting Equipment

Explanation: Given the scale of potential fires in the oil and gas industry, robust fire fighting equipment is necessary. High-capacity foam monitors, water cum foam monitors, and fire fighting robots are designed to deliver large volumes of fire suppressant with precision and control. These tools are crucial for tackling large fires in open areas, such as oil storage tanks and refinery units.

Details:

- Foam Monitors: Deliver large quantities of foam to suppress fires involving flammable liquids. Foam forms a blanket over the fuel surface, cutting off the oxygen supply and preventing re-ignition.

- Fire Fighting Robots: Can operate in hazardous environments without risking human lives, equipped with cameras and sensors for remote operation.

Training and Preparedness

Explanation: Training and preparedness are fundamental to effective fire safety. Personnel must be trained to operate fire fighting equipment, respond to emergencies, and execute evacuation plans. Regular drills and simulations help ensure that all employees are familiar with fire safety protocols and can act swiftly and confidently in the event of a fire.

Details:

- Comprehensive Training Programs: Include hands-on training with fire fighting equipment, theoretical knowledge about fire behavior, and emergency response procedures.

- Regular Drills: Simulate real-life scenarios to test the readiness of personnel and the effectiveness of fire safety plans.

Emergency Response Services

Explanation: In addition to on-site fire fighting capabilities, having access to emergency response services can be a lifesaver. These services provide rapid deployment of trained professionals and specialized equipment to manage large-scale fires and minimize damage. In remote and high-risk locations, emergency response teams can be the difference between a controlled incident and a catastrophic disaster.

Details:

- Rapid Deployment: Emergency response teams are equipped to quickly mobilize and reach the site of the fire, bringing with them specialized equipment and expertise.

- Professional Expertise: Teams are composed of trained fire fighting professionals who can assess the situation and implement effective fire suppression strategies.

Case Study: Effective Fire Safety Implementation

Explanation: Examining real-world examples of effective fire safety implementation provides valuable insights into best practices and innovative solutions.

Rim Seal Fire Protection Systems

Details:

- Application: Floating roof tanks used for storing oil are prone to rim seal fires. These fires occur at the seal between the floating roof and the tank wall, which can be difficult to detect and extinguish.

- Solution: Rim seal fire protection systems provide continuous monitoring and automatic suppression. They use sensors to detect heat or flames and activate suppression agents to quickly extinguish the fire.

Crash Fire Tenders

Details:

- Application: Oil refineries and offshore platforms require rapid response to fires due to the high risk of escalation.

- Solution: Crash fire tenders are specialized vehicles equipped with high-capacity foam and water monitors. They can navigate complex industrial environments and deliver large volumes of suppressant to control fires quickly.

Conclusion

The oil and gas industry faces unique and formidable fire safety challenges due to the nature of its operations and materials. Addressing these challenges requires a combination of specialized equipment, advanced detection technologies, robust fire fighting systems, comprehensive training, and rapid emergency response. By implementing these solutions, the industry can enhance its fire safety measures, protect lives, assets, and the environment, and ensure the continuity of its critical operations.

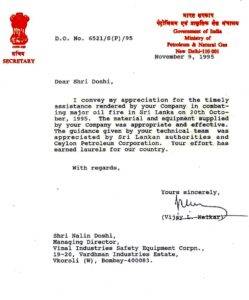

The journey towards fire safety in the oil and gas sector is ongoing, with continuous advancements and innovations driving improvements. Companies like Vimal Fire Controls play a crucial role in this journey, providing the expertise and technology needed to safeguard this vital industry. As we look to the future, the commitment to fire safety remains unwavering, ensuring that the oil and gas sector can operate safely and efficiently in even the most challenging conditions.